Inventory refers to the list of goods and materials that a company holds in stock, including the quantity of each item and its value. It is a crucial aspect of supply chain management and helps companies keep track of their assets, manage stock levels, and plan future orders. An accurate inventory management system is essential for ensuring smooth operations, meeting customer demands, and maintaining profitability.

Inventory management involves various strategies to effectively control and track the flow of goods in and out of a company's stock. Some of the key options include:

- Opening Stock

- Safety Stock

- Stock entry

- First In First Out (FIFO)

- Just-in-Time (JIT)

- Barcode scanning

- Inventory Software

- Cycle Counting

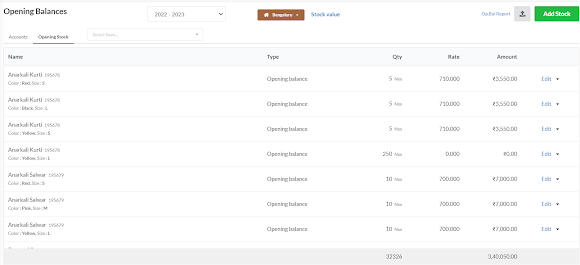

Opening Stock:

Opening stock is the stock of items the

company holds at the beginning of a financial year, or the stock of items

brought forward from the previous financial year to new financial year. You can

manage your opening stock under Accounting>Opening Balances > Stock.

The items added in Manage > Stock will

be displayed here.

Safety stock:

Safety stock is a level of inventory that a company maintains in order to mitigate the risk of stockouts (running out of stock) in the event of unexpected demand or supply chain disruptions. The goal of having safety stock is to ensure that there is enough inventory available to meet customer demand and avoid lost sales or dissatisfied customers.

First In First Out (FIFO):

FIFO (First In, First Out) is a method of inventory management that assumes that the first items to be added to inventory will be the first ones sold or used. This method assumes that the oldest items in inventory are sold or used first, before newer items. This approach can be useful for perishable items or items with a limited shelf life, as it helps to ensure that older items are used before, they become obsolete. In the context of stock accounting, FIFO is also used as a method for calculating the cost of goods sold and ending inventory value, where the cost of the oldest units is assumed to be the cost of the units sold.

You can choose the FIFO option in Settings> General

Just-in-Time (JIT) is a production and inventory control system in which goods are manufactured or delivered to the customer just as they are needed, rather than being produced or delivered in advance. The goal of JIT is to minimize the amount of inventory that a company holds and to reduce waste by producing only what is needed, when it is needed. JIT operates under the assumption that lead times are short and reliable, and that demand is constant and predictable. By closely coordinating production and delivery with demand, JIT aims to reduce inventory costs, improve efficiency, and increase responsiveness to customer needs. JIT is widely used in manufacturing and has been credited with reducing waste and improving the efficiency of many supply chains.

Barcode scanning:

Barcode scanning is the process of capturing and decoding the information stored in a barcode using a barcode scanner or smartphone camera. The information can then be used to identify a product, access information in a database, or trigger a specific action such as adding an item to a shopping cart. Barcodes are often used in retail, healthcare, and logistics to increase efficiency and accuracy in tracking products and data.

Inventory Software:

Inventory software is a computer program or set of programs that manage the stock of an organization. It helps keep track of products, materials or goods stored in a warehouse, shop or manufacturing unit. This software typically includes features like product tracking, stock management, order fulfillment, and reporting. The main goal of inventory software is to optimize inventory levels, minimize stock-outs and improve accuracy of inventory records.

Cycle Counting:

Cycle counting is an inventory management technique that involves counting a portion of a company's inventory on a regular basis, rather than counting all inventory items once a year. The purpose of cycle counting is to maintain accurate inventory records and to identify discrepancies between the physical count and the records. It helps organizations keep their inventory data up-to-date and ensures that inventory discrepancies are detected and corrected before they become significant problems.

Cycle counting can be done on a daily, weekly, or monthly basis, depending on the size of the organization and the turnover rate of inventory items. The items counted during a cycle count can be selected randomly or based on a specific criterion, such as high value items, fast-moving items, or items with a history of discrepancies.

Cycle counting can provide many benefits, including improved inventory accuracy, reduced inventory carrying costs, reduced shrinkage, and increased customer satisfaction.

Comments

Post a Comment